Course Vs Fine Thread

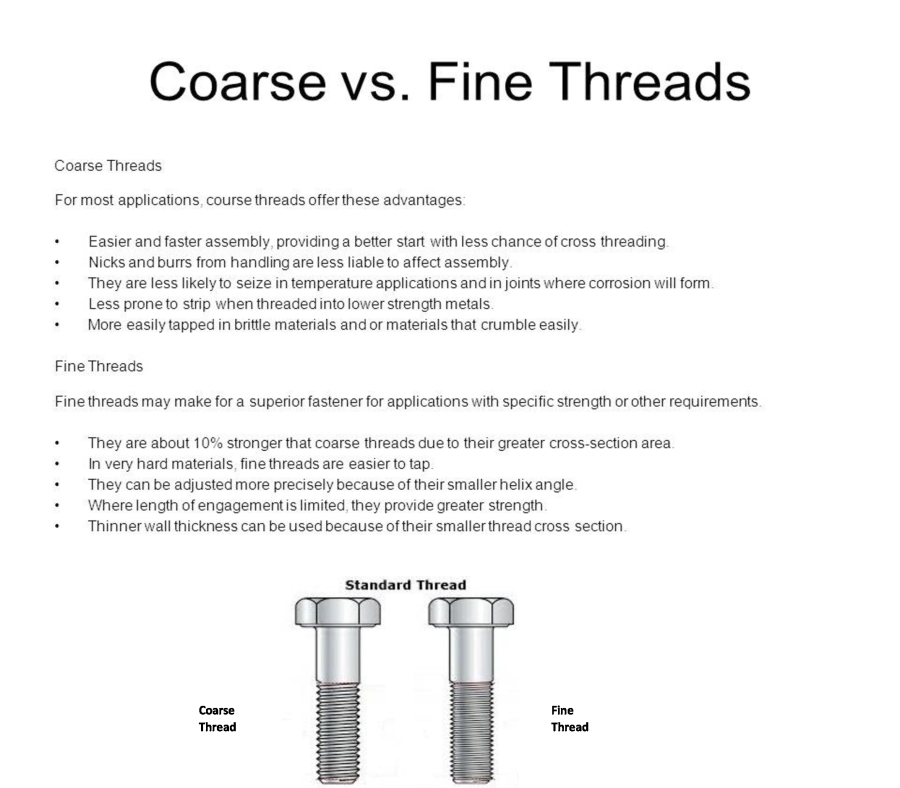

Course Vs Fine Thread - Web first let’s look at fine compared to coarse thread. Web a screw thread in conformity with this international standard is designated by the letter m followed by the values of the nominal diameter and of the pitch expressed in millimetres. One important consideration to make when selecting the right fastener is. Coarse threads are used when threaded into aluminum or cast iron because the finer. A 1/4 unf thread is about 14% stronger than its unc counterpart. Fine thread fasteners should be used in conjunction with thick gauge metal applications. Fine thread fasteners when you’re planning your next project, choosing the best fastener type is essential to the overall function of your final. Fine threads have more threads per inch so this will give you more gripping area in a smaller length. Web coarse thread is beneficial, because they are less likely to cross thread, more tolerant in adverse conditions and facilitate quick assembly. Coarse thread screws have a larger and deeper thread. Accessories includeddust collector includedaluminum bodylifetime warranty Web coarse threads have become the standard for most fastener applications, but when should fine threads be considered? Web the main difference between coarse thread screws and fine thread screws is the thread pitch and length. Coarse thread fasteners should be used in conjunction with thin gauge metal. Web a screw thread in conformity. Tpi stands for ‘threads per inch’, and is used to specific exactly how many. Accessories includeddust collector includedaluminum bodylifetime warranty Web coarse threads are much less likely to experience thread galling than fine threads. In addition, due to their distinct. Web as an industry standard, the plating needed for course thread bolts is 20% higher than the one required by. For example a 1/4″ bolt. Web as an industry standard, the plating needed for course thread bolts is 20% higher than the one required by fine threads. Fine thread series (unf/unrf) is. Fine thread fasteners when you’re planning your next project, choosing the best fastener type is essential to the overall function of your final. Web coarse threads are much. Fine thread fasteners should be used in conjunction with thick gauge metal applications. A 1/4 unf thread is about 14% stronger than its unc counterpart. Coarse thread screws have a larger and deeper thread. This is a frequently heard question at the kato tech group relative to both inserts and male. Web coarse thread vs. Web coarse threads are much less likely to experience thread galling than fine threads. A 1/4 unf thread is about 14% stronger than its unc counterpart. Coarse threads are used when threaded into aluminum or cast iron because the finer. Fine threads have more threads per inch so this will give you more gripping area in a smaller length. Web. Web coarse thread vs. Coarse threads are used when threaded into aluminum or cast iron because the finer threads. One important consideration to make when selecting the right fastener is. Web coarse threads are much less likely to experience thread galling than fine threads. Coarse thread screws have a larger and deeper thread. Web as an industry standard, the plating needed for course thread bolts is 20% higher than the one required by fine threads. Advantages of coarse threads one advantage of coarse threads is their capacity to easily grab. Fine thread fasteners when you’re planning your next project, choosing the best fastener type is essential to the overall function of your final.. Web see the loading charts below to see typical differences between the tensile strength of a fine vs coarse thread. Coarse thread screws have a larger and deeper thread. Advantages of coarse threads one advantage of coarse threads is their capacity to easily grab. Web a fine thread pitch means more threads, a course thread pitch means less threads. Web. Fine thread series (unf/unrf) is. Fine threads which is better, coarse threads or fine threads? A 1/4 unf thread is about 14% stronger than its unc counterpart. Fine thread fasteners should be used in conjunction with thick gauge metal applications. In addition, due to their distinct. Web as an industry standard, the plating needed for course thread bolts is 20% higher than the one required by fine threads. In addition, due to their distinct. Coarse thread fasteners should be used in conjunction with thin gauge metal. One important consideration to make when selecting the right fastener is. Fine threads have more threads per inch so this. Fine thread series (unf/unrf) is. Web see the loading charts below to see typical differences between the tensile strength of a fine vs coarse thread. Web coarse threads are much less likely to experience thread galling than fine threads. Fine threads have more threads per inch so this will give you more gripping area in a smaller length. Web as an industry standard, the plating needed for course thread bolts is 20% higher than the one required by fine threads. Coarse threads are used when threaded into aluminum or cast iron because the finer threads. Web a screw thread in conformity with this international standard is designated by the letter m followed by the values of the nominal diameter and of the pitch expressed in millimetres. Coarse threads are used when threaded into aluminum or cast iron because the finer. Web january 31, 2024 | 1:38 pm when it comes to fasteners, there’s more to them than just sizes and shapes. I am making some steering trees. Fine thread fasteners when you’re planning your next project, choosing the best fastener type is essential to the overall function of your final. Web coarse thread is beneficial, because they are less likely to cross thread, more tolerant in adverse conditions and facilitate quick assembly. Web coarse threads have become the standard for most fastener applications, but when should fine threads be considered? Web first let’s look at fine compared to coarse thread. Web coarse thread vs. Fine threads which is better, coarse threads or fine threads?

How to Choose the Right Screw Pitch The Repercussions of "Coarse" vs

Coarse Thread Vs. Fine Thread Fasteners All Points Fasteners

Coarse vs Fine thread? Is there a superior one? ToolHustle

A Quick Guide To Fastening MDF (+ The Best Screws For MDF)

Belmey industrial supplies

A Guide to Fastener Terminology WilsonGarner

How To Choose Coarse Thread Or Fine Thread For BoltsKnowledges News

Fine thread versus coarse thread screws

When to use Coarse or Fine Thread Kreg Screws? TheDIYPlan

Screw It! Intro to Fasteners & Bolted Connections Tarkka

For Example A 1/4″ Bolt.

Web A Fine Thread Pitch Means More Threads, A Course Thread Pitch Means Less Threads.

Fine Thread Fasteners Should Be Used In Conjunction With Thick Gauge Metal Applications.

This Is A Frequently Heard Question At The Kato Tech Group Relative To Both Inserts And Male.

Related Post: